产品分类 产品分类 友情链接 友情链接 |

|

您当前的位置: 首页 » » » 日本XEBEC陶瓷纤维油石 磨石信息

Click to enlarge |

| 产 品: |

| 单 价: |

450.00元/ |

| 最小起订量: |

1 |

| 供货总量: |

100 |

| 发货期限: |

自买家付款之日起 天内发货 |

| 更新日期: |

2026-02-07 03:05 有效期至:长期有效 |

| |

|

|

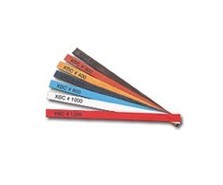

日本XEBEC陶瓷纤维油石 The standard Xebec Ceramic Fiber Stone.Excellent polishing performance for material under HRC57. 标准型陶瓷纤维油石。对硬度HRC57以下之材料拥有杰出的抛光性能。 | |

Features 特性 ·Through the utilization of aerospace materials (Alumina Fiber Filaments), breakage, cracking, and chipping have been eliminated. High polishing efficiency can be ensured. ·No clogging. Uniformly fine finishes can be achieved. ·Thanks to the braided structure of the rod type, high polishing efficiency is possible even with the side, of the tool, and there is no splitting of the tip. (#220 is designed in a two way liner structure) ·Suitable for fine deburring. ·Higher polishing efficiency can be achieved by using the Meister Finishi with tools (electric, air, ultrasonic) ·Coarse grit type made of thick Alumina Fiber Filaments is ideal for removing EDM scales. Only XEBEC can manufacture it. · ·本产品采用最适合研磨的结晶结构,实现了高研磨功效。 ·本品纤维交叉排列,可纵横向滑动,提高研磨速度及油石强度。 ·本品沙粒不易脱落,研磨工件表面不会有划痕产生。 ·研磨时几乎不会有热度产生,不会造成工件变热和油石劣化。 ·油石形状可任意修整,自由改变。

|

Structure 结构 | ■XEBEC's innovative Original Structure 首创的结构

|

| | ·No breakage during highe speed rotation!! ·Thanks to the braided structure, the side of the tool can polish! ·Polishing performance increases substantially when high-speed polishing becomes with a hand grinder!

|

| | Meister Finishi Rod Type Structure Meister Finishi rod type is braided structure of alumina fiber filaments. The structure below φ2mm or equivalent to #220(Gray) is as follows. 【Alumina fiber filaments structure】 The bundles of alumina fiber filaments cross and set in each other. 【Effect】 Not easy to break or tear, and longer tool life. Both a side and a tip of the tool can polish . Made of the plate as shown left photo. |

|

| ■Comparison in Structure and Features with Common Abrasive Stone 与普通油石的比较

|

| | XEBEC Meister Finish | common abrasive stone |

|---|

| Structure | | | | No breakage | No breakage even though it's only 0.5mm thick and 150mm long. Perfect for polishing on narrow areas such as ribs of plastic molds. | Sizes less than 3mm thick are not available as they are easy to break. So polishing narrow areas is impossible. | | Superior polishing efficiency | | Since it doesn't crack, high polishing efficiency can be achived when using it xith ultrasonic, air, electrical tools. | | Due to high ALF contents (up to 85%) high density and continuous cutting edges, superior polishing performance continues. |

| | As it breaks easily, not suitable for the use with ultrasonic, air, or electrical tools. | | Abrasive grain makes up only 30% total weight. | | Due to grain fall out, grinding performance is unstable and tool life is short |

| | No clogging | Thanks to the self –sharpening action, it resists clogging. Self-sharpening; ALF gradually cleaves by itself and generates new cutting edges, even though binders are consumed during polishing. | New cutting edges are generated after grain fall out.However, abrasive grains clog the blank holes created when the grains fall out .Easily clogged. | | Uniformed fine finishing | Thanks to the even diameter of ALF, surface roughness of the finished surface is superior. | Due to the variation of abrasive grains diameters, uniform finishes are difficult to achieve.. | | No chipping | Thanks to the continuous ALF, grains do not fall out and no scratching occurs. | Scratches are caused on the finished surface by fallen out grains. |

|

Usage, Applications 用途及应用范围 | ■Usage 用途

·Ideal for precise polishing of free surfaces, free curves, ribs, bosses, etc., of various forming molds (especially plastic mold). ·High finishing efficiency can be achieved without clogging, even for metals such as aluminum, copper, gun metal, etc., which clogs with common abrasive stones. ·Can be used in narrow areas where common abrasive stones cannot be used because of breaking. ·Use on complex shapes where uniform finishing could not be previously attained. ·Efficient EDM scales removal. ·陶瓷纤维油石(俗称超级油石)系将高纯度之陶瓷纤维与热塑性树脂结合制造而成,具有高硬度、耐磨耗及不易折断的特性。 ·除可用于手持研磨外,且适用于气动、电动往复式研磨机。在超音波振动研磨机上使用,效果最佳。 ·陶瓷纤维油石可在各种不同材质的模具钢上研磨加工。最适用于一般难研磨加工处,如窄沟壁、沟底、孔、滑痕、肋部及微小精细处。 ·尤其对于放电加工后积碳层的快速去除及抛光效果更佳。

| |

■Applications 应用范围

| Usage | Meister Finish (Stick type) 平板型 | Meister Finish (Rod type) 圆棒型 |

|---|

| Die and Mold Finishing | ·Removing EDM scales ·Polishing precise area ·Finishing ribs ·Finishing edges, corners

[Target] For resin, rubber, die castings etc. (Softer than HRC57) | ·Removing EDM scales ·Polishing precise areas ·Finishing edges, corners to be rounded ·Finishing bosses ·Finishing runners, sprues and sub-gates

[Target] For resin, rubber, die castings etc. (Softer than HRC57) | | Deburring | | ·Deburring parts for communication and optical instruments ·Fine deburring of nozzle ·Deburring edges of cutting tool blades . ·Fine deburring after machine processing

| | Others | | ·For dental molds (2.34) ·For metal-curving

|

|

Comparison 对比 | ■Performance Comparison with Competitors (SS)

|

|

| | ·The most widely used SS product is "Blue". (60% of all SS products) Please refer to the line graph. ·Users of S‘s “Blue” use it to achieve surface roughness shown by ·The same degree of surface roughness can be achieved by XEBEC's "Orange" ·For the user to achieve this surface roughness using S's "Blue" would result in the finishing removal rate shown in bar graph ;Using XEBEC's "Orange" would result in bar graph ,making it 4 times more efficient in polishing.

|

Use | ■Meister Finish (Stick type) 平板型

| |

| Efficient use 有效用法 | Picture 图片 |

|---|

Use the tip at an angle to the surface of a workpiece.使纤维油石与工作表面形成成一定角度。 | Approximately 5~45 degrees is effective. 最具效率的角度大约为 5~45 度。 |

| | Polishing and deburring using the side of the tool.使用油石侧边进行抛光或去毛刺。 | There is no polishing ability on the surface of the tools. 油石的正面不具有抛光能力。 |

| | Use with vibration tools (ultrasonic, air, electric etc.)配合往复工具使用(气动/电动超声波) | XEBEC Heat-Resistant Ceramic Abrasives are ideal for ultrasonic tools. XEBEC 耐热陶瓷油石是超声波工具的理想搭档 |

| Ideal tool length depends on each ultrasonic tool. If a tool is not mounted on the ultrasonic tool securely, exessive heat may be generated.要根据所使用的超音波工具选择适当的油石长度,如果油石没有夹紧,有可能会造成油石过热。 |

| | Forming (Shaping the tip of a tool in accordance with the shape of a workpiece.)Dressing 可根据需要将油石修正成型 | For easy and perfect dressing, use an electrodeposited diamond stone. Perform cutting same way. 可用金刚石油石轻松的进行修正 |

| | Coolant will increase efficiency.使用冷却液可提高工作效率。 | Coolant is recommend when polishing plastic molds. 进行塑料模具抛光时,推荐使用冷却液。 |

| | |

| ■Meister Finish (Rod type) 圆棒型

Thanks to braided structure, the side of the tool can polish !得益于辨状结构,油石的侧面可以用于抛光! |

| | | Efficient use 有效用法 | Picture 图片 |

|---|

Polishing and deburring using the tip or side of a tool.油石顶端和侧面均可用于抛光或去毛刺。 | Polishing using the entire surface of a tool is possible thanks to the braided Alumina Fiber stuructur. 得益于氧化铝辨状结构,油石的整个侧面都可用于抛光! |

| | Use with hand grinders or vibration tools (ultrasonic, air, electric etc.). 可配合手持研磨机或往复工具(气动/电动超声波)使用 | Use at less than the maximum rpm of 30,000 and less than 50mm in length. When using with ultrasonic tool, piease refer to “Stick type”. 请使用50mm以内的油石,最高转速请不要超过30,000rpm。 |

| | Forming(Shaping the tip of a tool in accordance with the shape of a workpiece.)Dressing可根据需要将油石修正成型 | For easy and perfect dressing, press a tool rotating in a hand grinder onto an electrodeposited diamond stone. Do cutting same way.可用金刚石油石轻松的进行修正Thanks to the braded structure, there is no splitting of the tip even when it is made into a fine point.得益于辨状结构,即使将尖端修整得极细也不会分叉。 |

| | Coolant will increase efficiency.使用冷却液可提高工作效率。 | Coolant is recommend when polishing plastic molds. 进行塑料模具抛光时,推荐使用冷却液。 |

| |

| |

■Meister

Stick type Lineup 平板型 |

|

| Dimensions(mm) | Red equivalent to #1200 | White equivalent to #1000 | Blue equivalent to #800 | Black equivalent to #600 | Orange equivalent to #400 | Light Brown equivalent to #300 | Dark Brown equivalent to #220 | Violet equivalent to #120 | | 0.3x4x100 | AR-0304M | AW-0304M | AB-0304M | AP-0304M | AO-0304M | AL-0304M | AD-0304M | - | | 0.4x4x100 | AR-0404M | AW-0404M | AB-0404M | AP-0404M | AO-0404M | AL-0404M | AD-0404M | - | | 0.5x4x100 | AR-0504M | AW-0504M | AB-0504M | AP-0504M | AO-0504M | AL-0504M | AD-0504M | - | | 0.5x4x150 | AR-0504L | AW-0504L | AB-0504L | AP-0504L | AO-0504L | AL-0504L | AD-0504L | - | | 0.5x6x100 | AR-0506M | AW-0506M | AB-0506M | AP-0506M | AO-0506M | AL-0506M | AD-0506M | - | | 0.5x6x150 | AR-0506L | AW-0506L | AB-0506L | AP-0506L | AO-0506L | AL-0506L | AD-0506L | - | | 0.5x10x100 | AR-0510M | AW-0510M | AB-0510M | AP-0510M | AO-0510M | AL-0510M | AD-0510M | - | | 0.5x10x150 | AR-0510L | AW-0510L | AB-0510L | AP-0510L | AO-0510L | AL-0510L | AD-0510L | - | | 0.8x4x100 | AR-0804M | AW-0804M | AB-0804M | AP-0804M | AO-0804M | AL-0804M | AD-0804M | - | | 0.8x4x150 | AR-0804L | AW-0804L | AB-0804L | AP-0804L | AO-0804L | AL-0804L | AD-0804L | - | | 0.8x6x100 | AR-0806M | AW-0806M | AB-0806M | AP-0806M | AO-0806M | AL-0806M | AD-0806M | - | | 0.8x6x150 | AR-0806L | AW-0806L | AB-0806L | AP-0806L | AO-0806L | AL-0806L | AD-0806L | - | | 0.8x10x100 | AR-0810M | AW-0810M | AB-0810M | AP-0810M | AO-0810M | AL-0810M | AD-0810M | - | | 0.8x10x150 | AR-0810L | AW-0810L | AB-0810L | AP-0810L | AO-0810L | AL-0810L | AD-0810L | - | | 1.0x1x100 | AR-1001M | AW-1001M | AB-1001M | AP-1001M | AO-1001M | AL-1001M | AD-1001M | - | | 1.0x2x100 | AR-1002M | AW-1002M | AB-1004M | AP-1002M | AO-1002M | AL-1002M | AD-1002M | AV-1002M | | 1.0x4x100 | AR-1004M | AW-1004M | AB-1004M | AP-1004M | AO-1004M | AL-1004M | AD-1004M | AV-1004M | | 1.0x4x150 | AR-1004L | AW-1004L | AB-1004L | AP-1004L | AO-1004L | AL-1004L | AD-1004L | AV-1004L | | 1.0x6x100 | AR-1006M | AW-1006M | AB-1006M | AP-1006M | AO-1006M | AL-1006M | AD-1006M | AV-1006M | | 1.0x6x150 | AR-1006L | AW-1006L | AB-1006L | AP-1006L | AO-1006L | AL-1006L | AD-1006L | AV-1006L | | 1.0x8x100 | AR-1008M | AW-1008M | AB-1008M | AP-1008M | AO-1008M | AL-1008M | AD-1008M | AV-1008M | | 1.0x8x150 | AR-1008L | AW-1008L | AB-1008L | AP-1008L | AO-1008L | AL-1008L | AD-1008L | AV-1008L | | 1.0x10x100 | AR-1010M | AW-1010M | AB-1010M | AP-1010M | AO-1010M | AL-1010M | AD-1010M | AV-1010M | | 1.0x10x150 | AR-1010L | AW-1010L | AB-1010L | AP-1010L | AO-1010L | AL-1010L | AD-1010L | AV-1010L | *1.5mm, 2.0mm and 3.0mm thickness products are available. |

■Meister Finish

Rod type Lineup 圆棒型 |

| Dimensions(mm) | Red equivalent to #1200 | White equivalent to #1000 | Blue equivalent to #800 | Black equivalent to #600 | Orange equivalent to #400 | Light Brown equivalent to #300 | Gray equivalent to #220 | | 1x50 | PR-10S | PW-10S | PB-10S | PP-10S | PO-10S | PL-10S | PM-10S | | 1x100 | PR-10M | PW-10M | PB-10M | PP-10M | PO-10M | PL-10M | PM-10M | | 1.5x50 | PR-15S | PW-15S | PB-15S | PP-15S | PO-15S | PL-15S | PM-15S | | 1.5x100 | PR-15M | PW-15M | PB-15M | PP-15M | PO-15M | PL-15M | PM-15M | | 2x50 | PR-20S | PW-20S | PB-20S | PP-20S | PO-20S | PL-20S | PM-20S | | 2x100 | PR-20M | PW-20M | PB-20M | PP-20M | PO-20M | PL-20M | PM-20M | | 2.34x50 | PR-234S | PW-234S | PB-234S | PP-234S | PO-234S | PL-234S | PM-234S | | 3x50 | PR-30S | PW-30S | PB-30S | PP-30S | PO-30S | PL-30S | PM-30S | | 3x100 | PR-30M | PW-30M | PB-30M | PP-30M | PO-30M | PL-30M | PM-30M | | 3x150 | PR-30L | PW-30L | PB-30L | PP-30L | PO-30L | PL-30L | PM-30L | | 6x50 | - | - | - | - | - | - | PM-60S | | 6x100 | - | - | - | - | - | - | PM-60M |

■Meister Finish

XEBEC Meister Finish Pencil Tipe & XEBEC Pencil Type Holder Lineup 新品:笔形油石和笔形油石夹 | Dimensions(mm) | Red equivalent to #1200(3 pieces packed) | Blue equivalent to #800(3 pieces packed) | CorrespondingPencil Type Holder | 0.5x0.5x50 | 3PACK-AR-0505S | 3PACK-AB-0505S | PCL-5 | 0.9x0.9x50 | 3PACK-AR-0909S | 3PACK-AB-0909S | PCL-9 |

Three stones are packed for one set of XEBEC Meister Finish Pencil Type. 每只包装有3根油石,不包括油石夹。 (XEBEC Pencil Type Holder is not included.) |

|

|