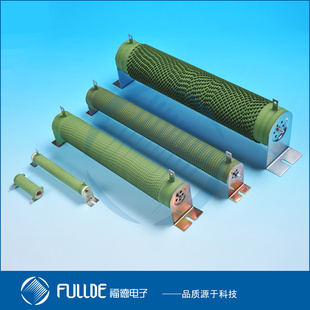

产品详细说明:

●产品特点 Features

1.体积小,耐震耐湿及良好的散热

2.完全绝缘,使用于电路板上绝缘度佳

3.耐短时间过负荷,低杂音,阻值经年无变化

4.使用氧化膜代替绕线可制作高阻值电阻

5.符合无铅/RoHS要求

●功率衰减曲线和温升曲线 Power Derationg Curve & Temp.Rise Curve

●电气规格 Electrical Specifications

项目Items 类别Style | 类别 Style | ||||||||

| 2W | 3W | 5W | 7W | 10W | 15W | 20W | |||

| 70℃额定功率Power at 70℃ | 2W | 3W | 5W | 7W | 10W | 15W | 20W | ||

| 最高工作电压Maximum Working Voltage | 250V | 350V | 500V | 500V | 1000V | 1000V | 1000V | ||

| 最高负荷电压Maximum Overload Voltage | 500V | 700V | 1000V | 1000V | 1000V | 1000V | 1000V | ||

| 绝缘电压Dielectric Withstanding Voltage | 1000V | 1000V | 1000V | 1000V | 1000V | 1000V | 1000V | ||

| 阻值范围Value Range | J(±5%) | 10Ω-1MΩ | 10Ω-100KΩ | 10Ω-100KΩ | 10Ω-100KΩ | 10Ω-100KΩ | 10Ω-100KΩ | 10Ω-100KΩ | |

| K(±10%) | 1Ω-22MΩ | 0.2Ω-1MΩ | 0.2Ω-1MΩ | 0.2Ω-1MΩ | 0.2Ω-1MΩ | 0.2Ω-1MΩ | 0.2Ω-1MΩ | ||

| 使用温度范围Operation Temp.Range | -55℃ ~ +155℃ | ||||||||

工作电压Rated Continuous Working Voltage (RCWV)=√PR,高于最高工作电压以最高工作电压为准.

●主要性能 Performance Characteristics

参考标准:JIS-C-5202

| 项目Items | 标准值Standard | 测试方法Test Methods | |||||||

| 短时间过负荷Short time overload | ±2% | 2.5倍额定电压/5秒2.5times RCWV/5seconds | |||||||

| 耐热性Resistance to solder heat | ±2% | 焊锡温度:350±10℃,时间:3秒Solder Temp. :350±10℃,time:3 seconds | |||||||

| 耐电压Dielectric withstanding voltage | 无烧毁或绝缘性破坏No breakdown or flashover | 依照电气规格表施加直流电压持续1分钟AC potential respectively specified in the list for 60 seconds. | |||||||

| 温度系数Temperature Coefficient | MOF :±350 PPM/℃绕线:–80 - +900PPM/℃ | 实验温度: 室温+100℃Test temperature: indoors Temp. 100℃ | |||||||

| 耐湿负荷Humidity Load Life | ±5% | 温度: 40±2℃,相对湿度:90-95%,1倍额定工作电压,时间1000小时(1.5小时开0.5小时关)Rated voltage 1.5hr ON,0.5hr OFF at 40±2℃,90-95&RH for 1000hrs | |||||||

| 负荷寿命Load Life | ±5% | 温度: 70±2℃,1倍额定工作电压,时间1000小时(1.5小时开0.5小时关)Rated voltage 1.5hr ON,0.5hr OFF at 70±2℃ for 1000hrs | |||||||

| 焊接强度Terminal Strength | 无引线脱落No evidence of mechanical damage or loosening terminals | 2.5公斤拉力,持续时间10秒2.5Kg for 10 seconds | |||||||

| 可焊锡性Solderability | 吃锡面积95%以上At least 95% coverage | 焊锡温度:235±5℃,时间:2±0.5秒235±5℃ for 2±0.5 seconds | |||||||

●料号编码 Part Number

发布供求信息

发布供求信息 推广企业产品

推广企业产品 建立企业商铺

建立企业商铺 在线洽谈生意

在线洽谈生意